1、 Characteristics of LTCC slurry

1. Complete supporting slurry product system

Advanced Institute Technology provides users with a complete matching slurry product system for A6, 951, 9K7, and domestic commercial ceramic films. Whether it is

Internal/External Electrode SlurryThrough hole slurry, end slurry

resistor pasteWhether it is solder paste, cavity paste/film, etc., the company can provide high-quality solutions to meet various needs of users.

2. Core materials independently developed

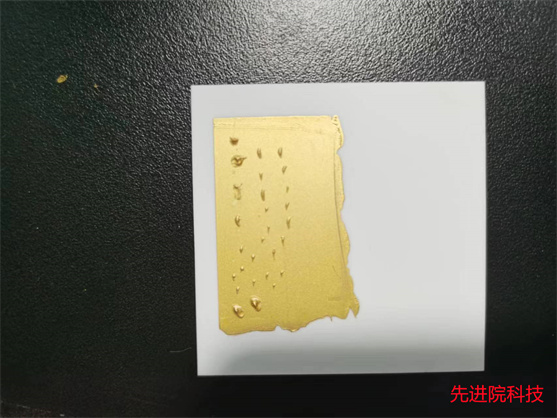

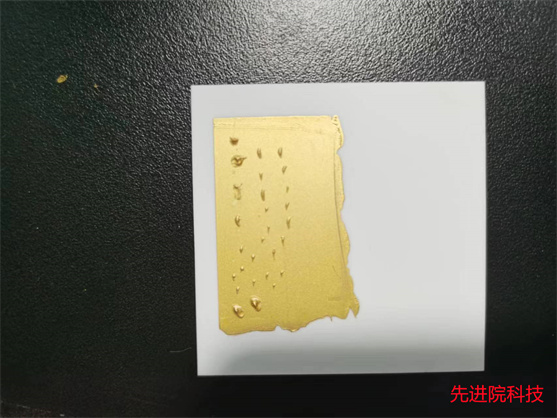

The core materials used in the slurry include metal powder, glass powder, etc., all of which have been independently developed. This means that the quality of both gold, silver, and their mixed internal/external electrode slurries, as well as various other slurries, can be effectively controlled, stable, and reliable.

1. Ideal choice for high-density integrated device molding and packaging technology

Low temperature co fired LTCC slurry is a high-density integrated device molding and packaging technology. Compared to traditional packaging technology, it has higher integration and faster production speed. It is not only widely used in consumer electronics products such as mobile phones and televisions, but also plays an important role in fields such as automotive electronics and medical equipment.

2. Rich selection options

The complete matching of LTCC slurry system allows users to choose the appropriate slurry according to their own needs. Whether it requires conductive paste such as gold or silver, or

resistor pasteHigh quality solutions such as solder mask paste can be found to meet the needs of different applications.

1. Core materials with stable quality ensure reliable performance

The independently developed core materials enable effective control of the quality of LTCC slurry. During the production process, this stable quality ensures the reliable performance of the device. For example, reliable internal/external electrode slurries can provide good conductivity, resistance slurries can provide accurate resistance values, solder mask slurries can provide excellent packaging effects, cavity slurries/membranes can achieve high integration, and so on.

2. Safe and controllable material assurance for the production process

Safety is crucial in the production process using LTCC slurry. The independently developed core materials not only have reliable quality, but also ensure the safety of the production process. This is of great significance for ensuring the continuity and stability of production.

2、 The Development Prospects of LTCC Slurry

1. Continuously growing market demand

With the development of electronic information technology, the demand for highly integrated devices is also increasing. LTCC slurry, as a high-density integrated device molding and packaging technology, has broad market prospects. From consumer electronics to automotive electronics, medical devices, and other fields, LTCC paste can play an important role.

2. Technological innovation drives industry development

As a technology independently developed by Advanced Institute Technology, LTCC slurry maintains a leading position in technology. Through continuous technological innovation and collaboration, LTCC slurry will be able to better meet market demand, expand application areas, and promote the development of the entire industry.

Summary:

Low temperature co fired LTCC slurryAs a high-density integrated device molding and packaging technology, it has rich selectivity, stable core material quality, and safe and controllable production process guarantee. In the current and future markets, it will play an important role in meeting the growing demand for highly integrated devices. Through technological innovation and collaboration, LTCC pulp will continue to develop and drive progress in the entire industry.