The working principle of electromagnetic protection absorbing patch is to absorb the energy of electromagnetic waves through the dielectric and magnetic losses inside the material, and convert it into thermal energy. When electromagnetic waves enter the surface mount material, the dielectric polarization and hysteresis effect inside the material will cause energy loss, thereby reducing the energy reflected back to the source end. In addition, by designing different types of patch structures, effective absorption of electromagnetic waves within a specific frequency range can be achieved.

Material characteristics

Electromagnetic protection absorbing patches usually have the following characteristics:

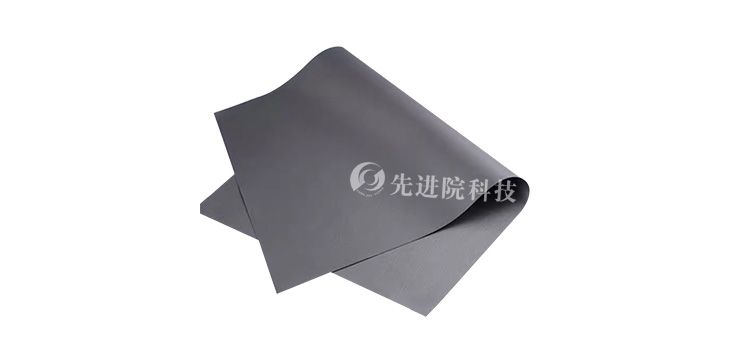

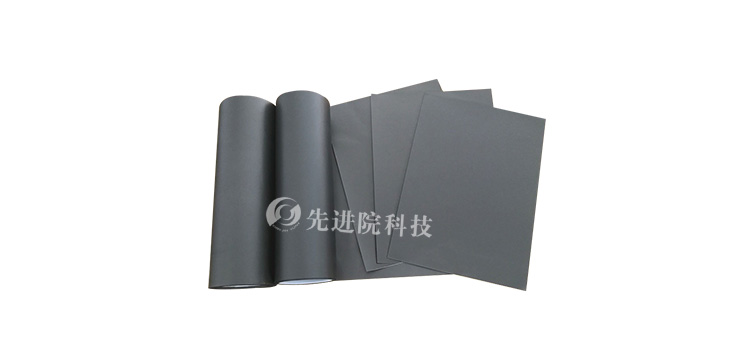

- Lightweight: Surface mount materials are usually very thin and lightweight, without adding too much weight.

- Easy to install: SMT materials usually come with adhesive backing, which can be easily attached to various surfaces.

- Broadband absorption: capable of absorbing electromagnetic waves over a wide frequency range, suitable for multiple frequency bands.

- Environmental adaptability: able to maintain good absorption performance under different environmental conditions.

- Flexibility or rigidity: Depending on the application requirements, the patch can be flexible (such as rubber substrate) or rigid (such as composite material).

Main components

Electromagnetic protection absorbing patches are usually composed of the following components:

- Matrix material: As a supporting structure, it can be a polymer film (such as polyimide, polyester, etc.), rubber, or composite material.

- Filler materials: fillers used to enhance absorption performance, including dielectric fillers (such as carbon black, carbon nanotubes, graphene, etc.) and magnetic fillers (such as ferrite, carbonyl iron powder, etc.).

- Adhesive: used to tightly bond the above components together and provide the adhesive function of the patch.

Preparation Method

Electromagnetic protection absorbing patches can be prepared by various methods:

- Coating method: Mix the absorbing filler with the substrate material and coat it on the surface of the substrate, then cure it by heating to form an absorbing layer.

- Laminated technology: laminating multiple layers of materials with different functions together to form composite absorbing patches.

- Printing technology: Using printing technology to print absorbing materials on substrates, forming absorbing patches with specific patterns.

- 3D Printing: Utilizing advanced 3D printing technology, absorbing patches are constructed layer by layer according to the design model.

application area

Electromagnetic protection absorbing patches are widely used in multiple fields, including but not limited to:

- Military and Defense: Used for stealth technology to reduce radar cross section (RCS) and improve the stealth performance of aircraft, missiles, etc.

- Aerospace: Reduce electromagnetic reflection and improve electromagnetic compatibility in equipment such as satellites and airplanes.

- Communication equipment: Reduce electromagnetic interference (EMI) and improve signal quality, especially in wireless communication systems.

- Electronic devices: Used in consumer electronic devices to reduce interference between internal components.

- Medical equipment: Reduce the impact of electromagnetic noise on sensitive medical equipment.

- Laboratory testing: used to establish electromagnetic shielding rooms or testing darkrooms, providing a non reflective electromagnetic environment.

- Automotive industry: Reduce electromagnetic interference inside cars and improve driving experience.