Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

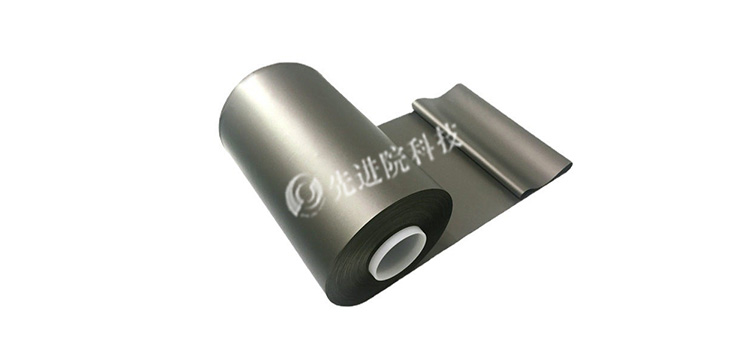

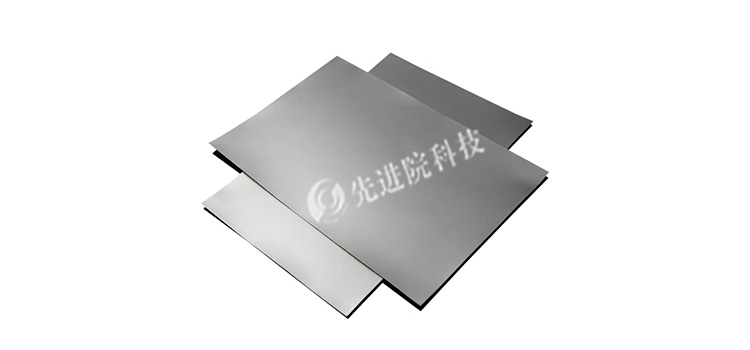

With the development of electronic technology, the demand for high-performance electromagnetic materials is constantly increasing. Especially in wireless communication, electronic device shielding, and absorbing material applications, the requirements for magnetic isolation sheets are particularly strict.Yanbo brand high permeability and low loss magnetic isolation sheetWith its excellent magnetic properties and low loss characteristics, it occupies a place in the market. In order to further improve its performance, especially in terms of surface quality, advanced electroplating processes are particularly important.

The high permeability and low loss magnetic isolation sheet of Yanbo brand is made ofAdvanced Institute (Shenzhen) Technology Co., LtdA special material developed with high magnetic permeability and low loss factor, widely used in electromagnetic compatibility (EMC) solutions in various high-frequency environments. Good surface quality is crucial for maintaining these key performance parameters, therefore optimizing the electroplating process has become a key step in improving product quality.

Electroplating is a method of depositing metal onto a substrate through electric current, which provides a protective film or functional coating for the magnetic separator, thereby improving its physical and chemical properties. For high magnetic conductivity and low loss magnetic separators, the ideal plating layer should be able to enhance their magnetic conductivity and corrosion resistance while maintaining low loss characteristics.

Ensuring the cleanliness of the workpiece surface is the foundation for obtaining high-quality coatings. Proper pretreatment steps such as degreasing, acid washing, and activation can effectively remove oil stains, oxides, and other pollutants, ensuring uniform deposition of metal ions during subsequent electroplating processes.

After completing electroplating, implementing appropriate post-processing such as cleaning, drying, and heat treatment can help release internal stress, eliminate microcracks, and strengthen the adhesion between the coating and the substrate.

In addition to the traditional electroplating process improvements mentioned above, it is also possible to consider incorporating absorbing materials into the design of magnetic separators. For example, adding specific components of absorbers during the electroplating process not only endows it with excellent magnetic conductivity, but also absorbs electromagnetic waves within a certain range, thereby expanding its application fields.

In summary, by continuously exploring and improving the electroplating process, significant improvements can be madeYanbo brand high permeability and low loss magnetic isolation sheetThe surface quality meets the growing market demand. Advanced Institute (Shenzhen) Technology Co., Ltd. will continue to be committed to technological innovation and provide customers with higher quality electromagnetic material solutions.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2