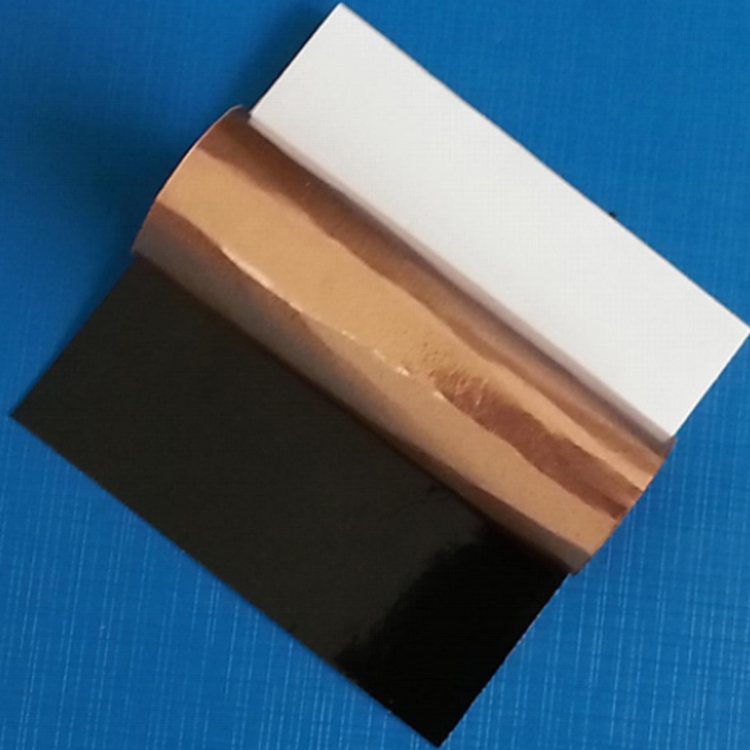

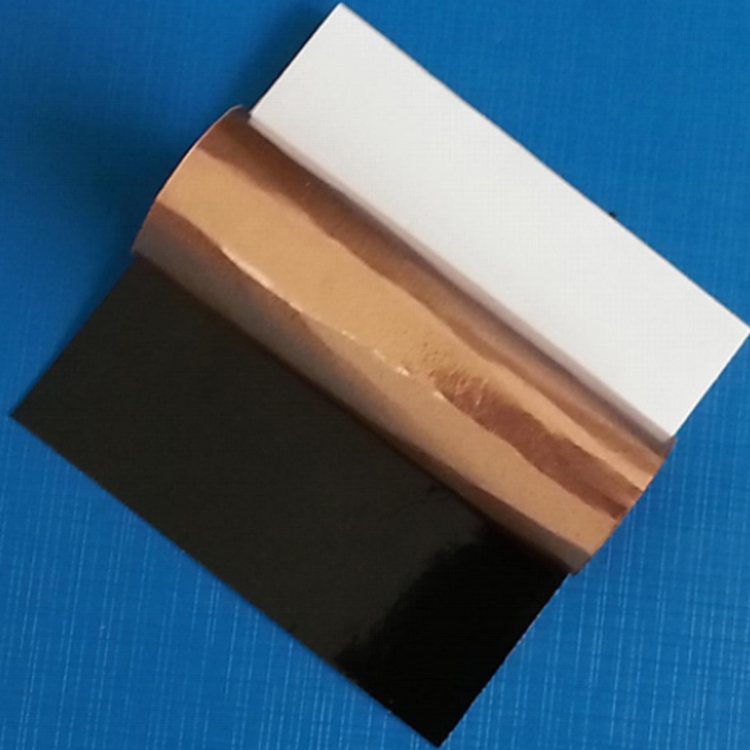

Conductive meshIt is a composite material composed of conductive fibers and conductive fillers, with good conductivity and electromagnetic interference resistance. It can not only be used as an electromagnetic shielding material, but also as a conductive material, with broad application prospects.

There are three main methods for preparing conductive mesh: chemical plating, electrostatic spraying, and chemical cross-linking. Among them, chemical plating is the process of mixing conductive fibers with other materials to form an electroplated layer through chemical reactions; Electrostatic spraying is the process of mixing conductive fiber film with polymer resin to form a coating through electrostatic adsorption; Chemical crosslinking method is to mix conductive fibers with polymer resin and form a coating through chemical crosslinking reaction.

The performance characteristics of conductive mesh mainly manifest in the following aspects:

Conductivity:Conductive mesh has good conductivity and can be connected into circuits through chemical bonds, thereby achieving electromagnetic shielding and anti-interference purposes.

Anti electromagnetic interference performance:Electromagnetic interference is usually caused by external or internal electromagnetic interference, such as mobile communication, broadcasting, radar, etc. These interferences may have an impact on electronic devices, thereby affecting their shielding effectiveness. Conductive mesh has good resistance to electromagnetic interference and can maintain its stability in various environments.

Mechanical properties:Conductive mesh has good mechanical properties and can withstand harsh environmental conditions such as electromagnetic interference and vibration.

Corrosion resistance:Conductive mesh has good corrosion resistance and can be used for a long time under various environmental conditions.

Low price:Conductive mesh has a lower price and can effectively protect electronic devices in terms of cost.

However, conductive mesh also has some drawbacks, such as its conductivity being easily affected, unstable mechanical properties, and weak corrosion resistance. Therefore, in applications, selection and evaluation need to be based on specific needs.

The selection of conductive mesh requires consideration of multiple factors, and the following are some possible selection considerations:

The usage requirements of conductive mesh: Different application scenarios also have different demands for conductive mesh.

For example, shielding materials are commonly used in electronic devices to reduce the impact of electromagnetic interference on equipment and personnel. Therefore, when choosing conductive mesh, it is necessary to determine its usage requirements based on the application scenario to ensure that it can meet the usage needs.

The conductivity of conductive mesh is an important factor affecting its application. If the conductivity of the conductive mesh is poor, it may cause signal reception and transmission to be obstructed, affecting its practical application effect.

Therefore, when selecting conductive mesh, it is necessary to ensure that its conductivity meets the requirements and that it can achieve electromagnetic shielding and anti-interference through reasonable chemical bonding and physical connection.

Too large or too small conductive mesh may affect its shielding effect and service life, while too small conductive mesh may limit the selection of parameters such as length and width. Therefore, when choosing conductive mesh, it is necessary to consider whether its size and quality meet the requirements.

The cost of conductive mesh: Due to its low cost, conductive mesh may not be one of the most suitable electromagnetic shielding materials. However, if you choose conductive mesh that is too expensive or of poor quality, it may waste resources and costs.