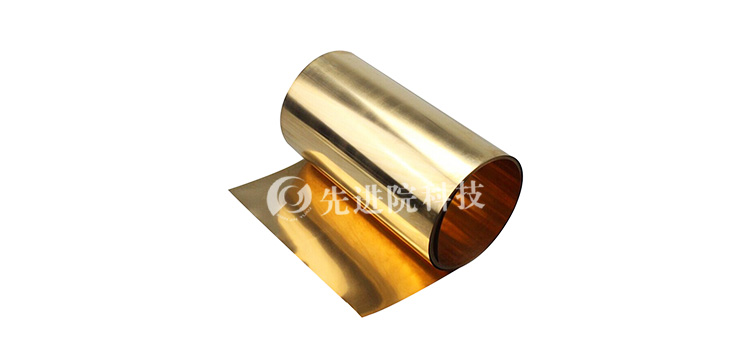

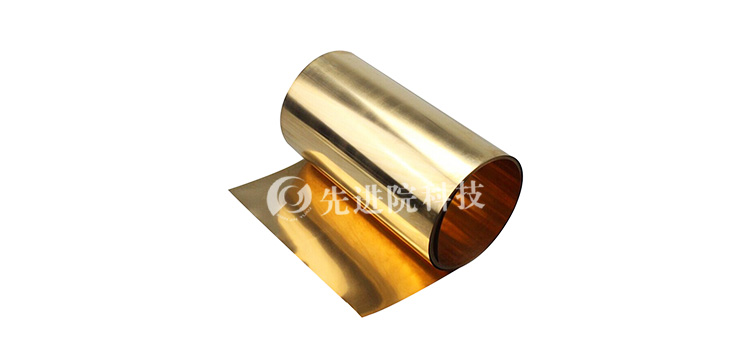

Laser is a device specifically designed to generate high-intensity, high concentration, and high monochromaticity light energy, widely used in medical, communication, scientific research, and other fields. Femtosecond laser is a type of laser that can generate ultra short pulse lasers and has special application requirements. Silver plated, gold plated, and aluminum plated reflective films can meet these needs and become important components in femtosecond lasers.

Silver plated film reflectorHas high reflectivity in femtosecond lasers. The average reflectivity in the range of 450-2000nm can reach over 97.5%, and the reflectivity in the range of 2-20um can also reach over 96%. This high reflectivity enables femtosecond lasers to more efficiently focus laser energy on the target object, thereby achieving more precise treatments or experiments.

At the same time, silver plated reflective mirrors have good stability and durability. In order to increase its durability and prevent oxidation, the outermost layer is often coated with a SiO2 protective layer, which not only improves reflectivity but also enhances the strength of the lens. However, due to the relatively soft and easily scratched silver film, it is necessary to avoid high humidity environments and take careful wiping measures during use.

The application of high reflective film mirrors in femtosecond lasers goes far beyond this. Femtosecond lasers are commonly used in the medical field for ophthalmic surgery, skin optical preparation, etc. The high reflectivity of high reflective film mirrors enables the laser to more accurately irradiate the affected area, improving the treatment effect. Meanwhile, high reflective film mirrors are also widely used in scientific research experiments, such as laser physics research, nanotechnology experiments, and other fields.

However, the application of high reflectivity films in lasers still faces some challenges and limitations. For example, the cost of preparing high reflective films is high and requires specialized technology and equipment. In addition, high humidity environments and careless wiping may affect the service life and performance of the reflector. Therefore, it is necessary to maintain an appropriate environment and pay attention to usage details in lasers with high reflectivity coatings.

Overall,

Silver plated, gold plated, aluminum plated reflective filmThe application of high reflection film in lasers is of great significance. Their high reflectivity and good stability enable femtosecond lasers to work more efficiently and accurately, driving the development of laser technology. However, it is still necessary to pay attention to certain maintenance and upkeep during use to extend the lifespan of the lens and maintain its excellent performance.