Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

The lightning protection grounding wire clamp and lightning protection grounding copper braided tape consist of three parts. The grounding system has a unique design, flexible equipment, and quick installation, which effectively solves the innovative problem of lightning protection grounding for solar photovoltaic systemsConductive gasketThe problem.

The grounding system is designed as the most widely used photovoltaic grounding method internationally, suitable for photovoltaic roofs, photovoltaic floors, photovoltaic carports, and photovoltaic systems

Application of lightning protection and grounding for solar photovoltaic systems such as vegetable greenhouses.

The system is made of materials such as stainless steel SUS304, aluminum AL6005-T5, and copper, and has undergone special surface treatment to ensure reliable quality

Suitable for various installation environments. The system has passed the following tests: thermal cycling (80 ° C to -20 ° C), high-temperature accelerated aging test, and saltwater rinsing

Testing.

Strong compatibility: This system is suitable for almost all solar panels with frames on the market, and is compatible with common photovoltaic roof brackets, aluminum rails, and ground brackets

Aluminum guide rails, photovoltaic carports, and C-shaped steel (U-shaped steel) guide rails are matched and have a wide range of applications.

The grounding system comes with a 10-year warranty.

Installation location: photovoltaic systems on roofs, floors, carports, etc

Material: Stainless steel SUS304, AL6005-T5 and copper

Surface treatment: Tin plating or nickel plating

Design standards: ANSI/UL467, UL2703, and CSA

Compatible rails: Aluminum rails (roof/floor/carport)

C-shaped steel (U-shaped steel)

Customer customization: Provide OEM/ODM customized production

Puncture the anodized layer on the module frame and guide rail to achieve current conduction between the solar module frame and the installation guide rail.

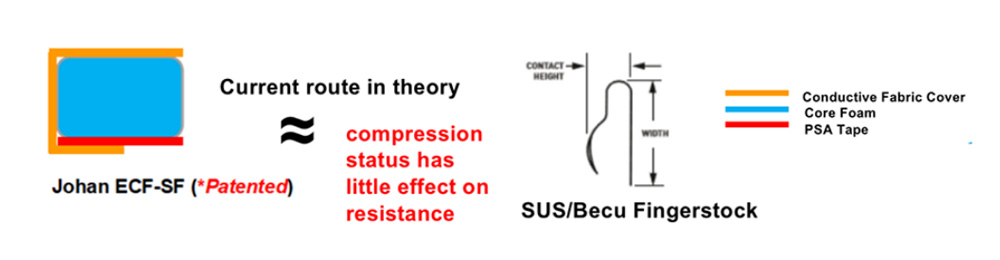

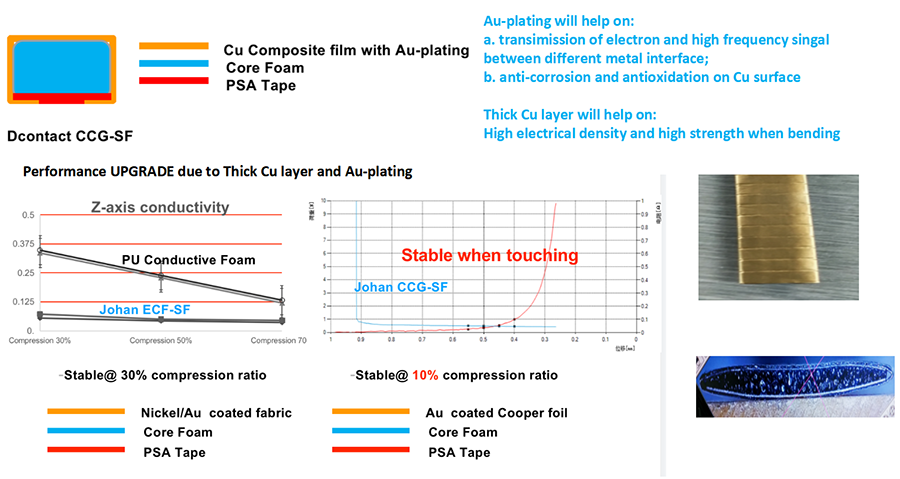

The basic structure and composite current do not pass through PSA

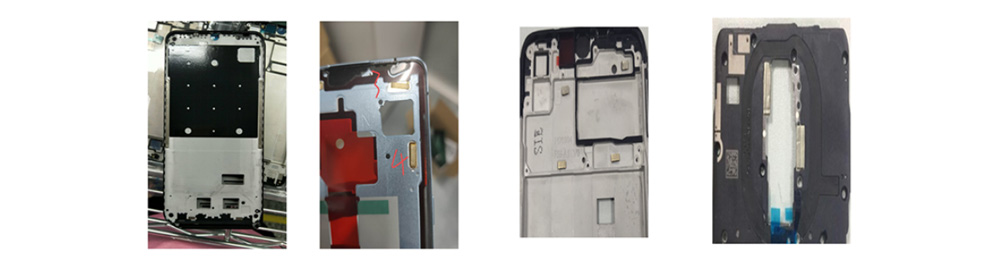

LCD with iron frame screen, OLED screen, motherboard, small board bracket, camera grounding, camera decorative ring

Product List

performance

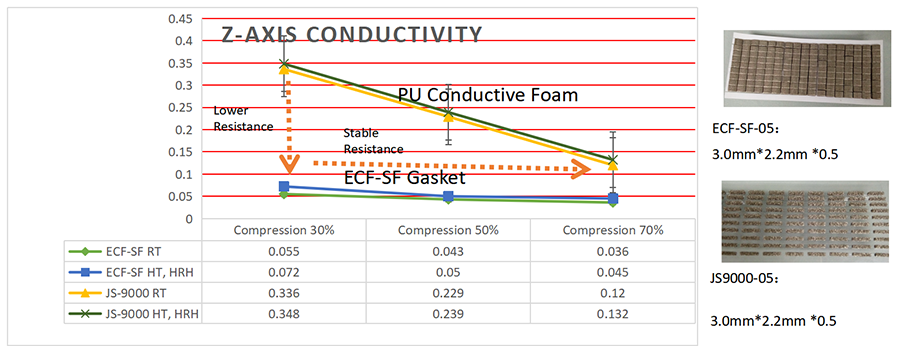

Testing equipment:

Aging machine/compression tester

Compression ratio:

30%, 50%, 70%

Testing method:

a) Operating conditions: High temperature (HT) 80 °, low temperature (LT) -20 °; 80% RH (Royal Highness);

Place the sample in the aging machine room. Run at high temperature for 1 hour, run at low temperature for 1 hour, 2 hours per cycle, run for 12 cycles (total 24 hours);

b) Complete the cycle and leave it at room temperature for 1 hour

c) Measure resistance after compression

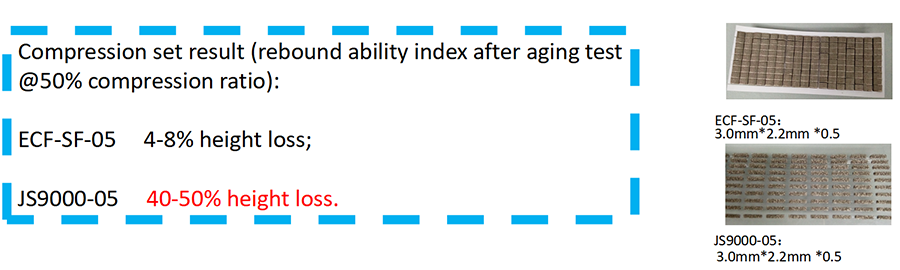

Reliability Studies

Testing equipment:

Aging machine/compression tester

Compression ratio: 50%

Testing method:

a) Operating conditions: High temperature (HT) 80 °, low temperature (LT) -20 °; 80% RH (Royal Highness);

Compress the sample by 50% and place it in the aging machine room. Run at high temperature for 1 hour, run at low temperature for 1 hour, 2 hours per cycle, run for 12 cycles (total 24 hours);

b) Complete the cycle and leave it at room temperature for 1 hour

c) Measure natural height

The basic structure and composite current do not pass through PSA

Dynamic environmental reliability

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2