Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

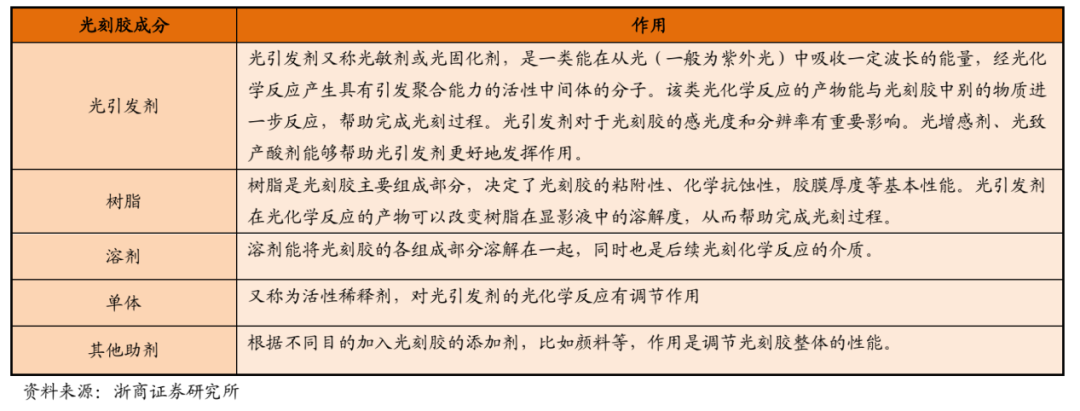

photoresistAlso known as photoresist, it is a mixed liquid that is sensitive to light. Its components include: photoinitiators (including sensitizers and acid generators), photoresist resins, monomers, solvents, and other additives. Photoresist can transfer the required fine patterns from the photomask (mask) to the substrate to be processed through photolithography processes such as exposure and development through photochemical reactions. Depending on the usage scenario, the substrate to be processed here can be integrated circuit material, display panel material, or printed circuit board.

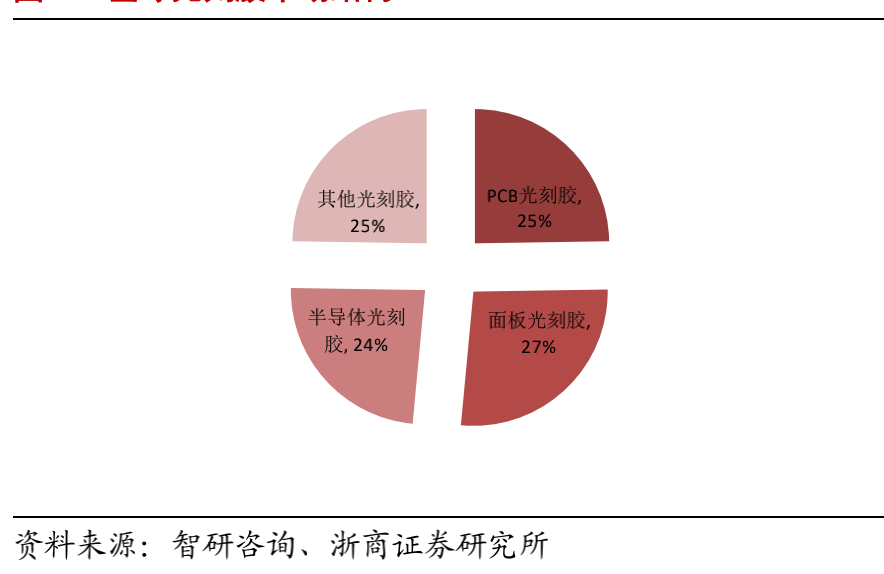

According to statistics from third-party organization Zhiyan Consulting, the global photoresist market is expected to reach nearly 9 billion US dollars in 2019, with a CAGR of approximately 5.4% since 2010. It is expected that the market will continue to grow at an average annual rate of 5% in the next three years, and the global photoresist market size will exceed 10 billion US dollars by 2022. According to their application fields, photoresist can be classified into PCB photoresist, display panel photoresist, semiconductor photoresist, and other photoresists. The market structure of different types of photoresist in the global market is relatively balanced, and the specific proportion can be shown in the following figure.

(Global photoresist market structure)

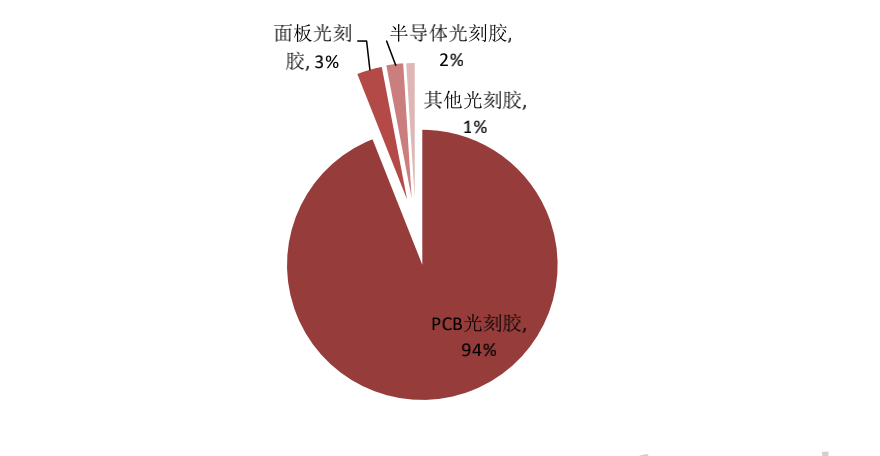

According to data from Zhiyan Consulting, benefiting from the trend of the semiconductor, display panel, and PCB industries moving eastward, the annual growth rate of domestic photoresist supply in China has reached 11% since 2011, higher than the global average of 5%. In 2019, the sales scale of local enterprises in the Chinese photoresist market was about 7 billion yuan, accounting for about 10% of the global market, with huge development space. At present, China's domestic photoresist is mainly used for PCB photoresist, and the supply of photoresist for flat panel displays and semiconductors is extremely low. The production structure of domestic photoresist enterprises in China can be shown in the figure.

(Production structure of domestic photoresist enterprises in China)

Classification of photoresist

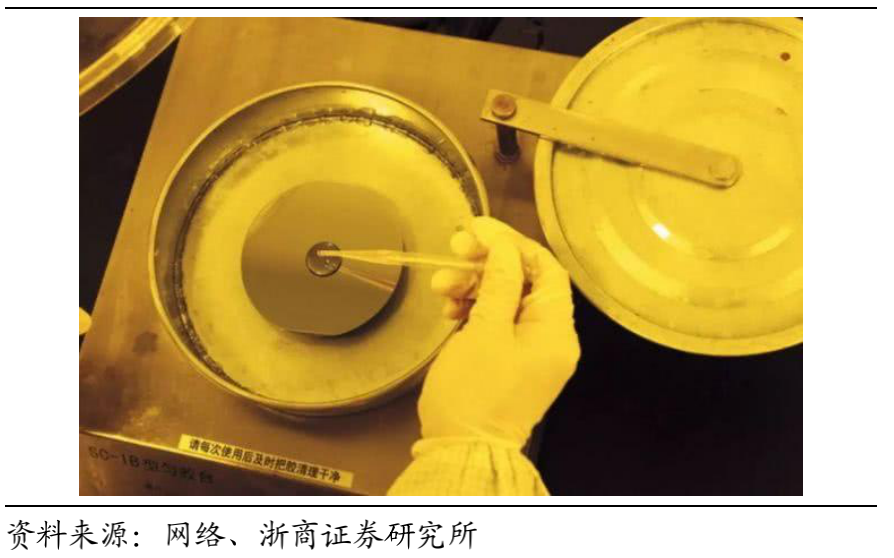

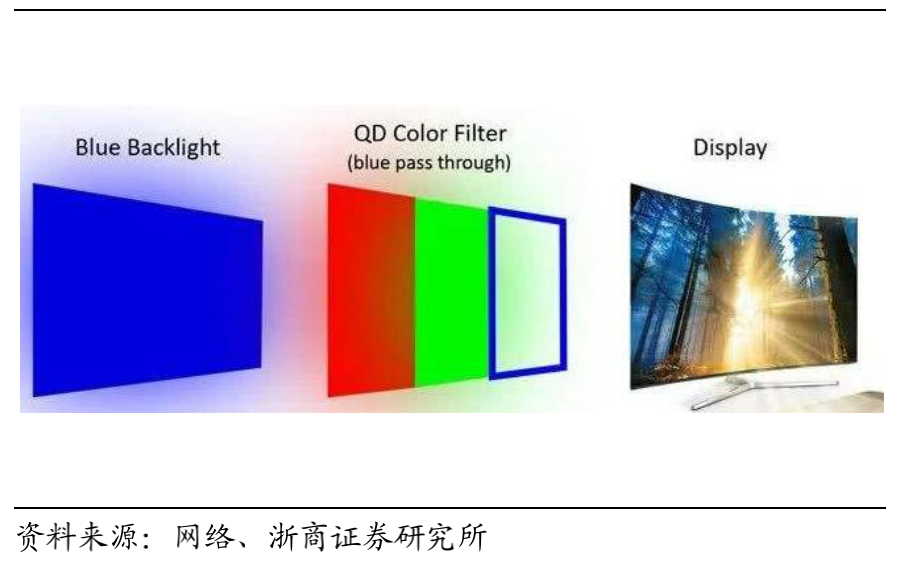

In the tablet display industry; The main photoresist used includes color and black photoresist, LCD touch screen photoresist, TFT-LCD positive photoresist, etc. In the photolithography and etching production process, photoresist is coated on the surface of crystal films, and the patterns on the photomask (mask) are transferred to the film through exposure, development, and etching processes, forming geometric patterns corresponding to the mask.

(photoresist coating process)

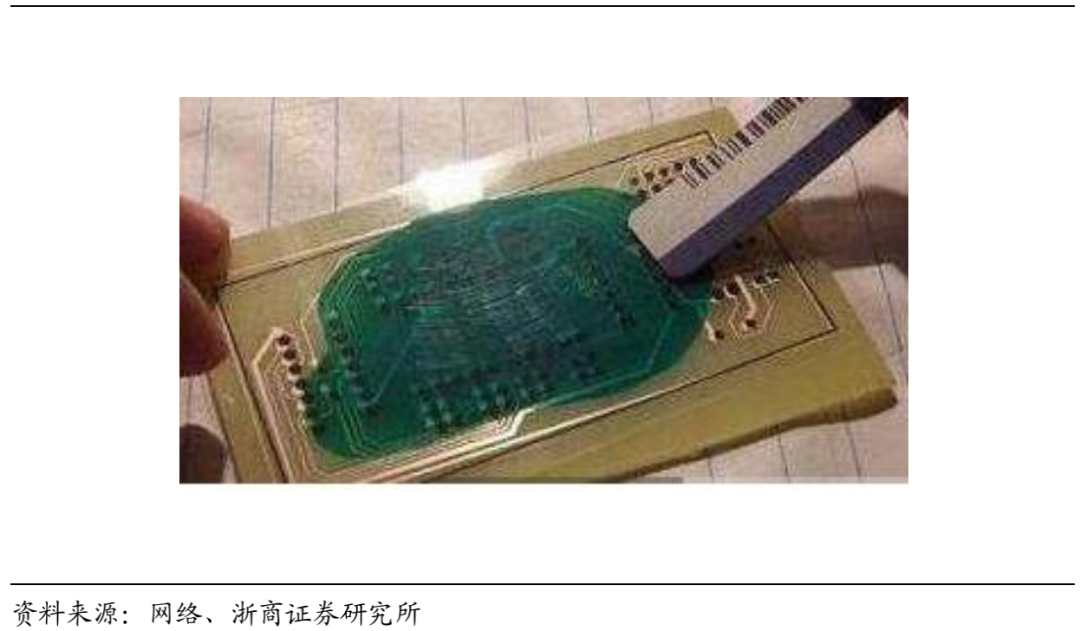

In the PCB industry; The main photoresist used includes dry film photoresist, wet film photoresist, photosensitive solder mask ink, etc. Dry film is a special thin film applied to a processed copper-clad board for exposure and development; Wet film and photo imaging solder mask ink are coated on the copper-clad board and exposed for development after drying. Dry film and wet film each have their own advantages. Overall, wet film photoresist has a higher resolution than dry film and is cheaper. It is replacing some of the markets for dry film photoresist.

The manufacturing of color filter films for LCD screens relies on color photoresist

In the semiconductor integrated circuit manufacturing industry; Mainly using g-line photoresist, i-line photoresist, KrF photoresist, ArF photoresist, etc. In the manufacturing process of large-scale integrated circuits, silicon wafers are generally subjected to more than ten photolithography processes. In each photolithography and etching process, the photoresist needs to be transferred from the photomask (mask) to the silicon wafer through pre baking, coating, pre baking, alignment, exposure, post baking, development, and etching.

(Photo sensitive solder mask ink for PCB)

Photoresist is an important material for integrated circuit manufacturing: the quality and performance of photoresist are key factors affecting the performance, yield, and reliability of integrated circuits. The cost of photolithography process is about 35% of the entire chip manufacturing process, and it consumes about 40% -50% of the entire chip process time. The photoresist material accounts for about 4% of the total cost of IC manufacturing materials, and the market is huge. Therefore, photoresist is the core material for semiconductor integrated circuit manufacturing.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2