Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

A monitor is an I/O device belonging to a computer, which is a display tool that displays certain electronic files on the screen through a specific transmission device and reflects them back to the human eye. In a broad sense, displays such as large screens, televisions, BSV LCD splicing fluorescent screens, mobile phones, and QuickPass screens that can be seen everywhere on the streets are considered as displays, generally referring to display devices connected to computer hosts.

1. The fatal nemesis of electronic products is high temperature, as it can lead to a series of problems such as decreased reliability, unstable performance, and shortened service life of electronic products. Display screens are also afraid of high temperatures, so engineers have adopted various methods to control the temperature of electronic components inside the display screen, so that it does not exceed the specified higher allowable temperature under the working environment conditions of the display screen, in order to solve the heat dissipation problem.

2. In fact, when choosing a cooling method, we need to consider the following issues: heat flux density, volumetric power density, total power consumption, surface area, volume, working environment conditions (temperature, humidity, air pressure, dust, etc.) of the display screen.

3. According to the principle of thermal conductivity, there are natural cooling, forced air cooling, and direct liquid cooling; Evaporative cooling; Thermoelectric cooling; Heat pipe heat transfer and other heat dissipation methods.

1. Fan cooling, using a long-lasting and high-energy fan inside the lamp housing to enhance heat dissipation, is a commonly used method with low cost and good effect.

2. Using aluminum heat dissipation fins is a common method of heat dissipation, where aluminum heat dissipation fins are used as part of the casing to increase the heat dissipation area.

3. Aerohydrodynamics utilizes the shell shape to create convective air, which is a low-cost method for enhancing heat dissipation.

4. Surface radiation heat dissipation treatment, the surface of the lamp shell is subjected to radiation heat dissipation treatment. A relatively simple method is to apply radiation heat dissipation paint, which can remove heat from the surface of the lamp shell through radiation.

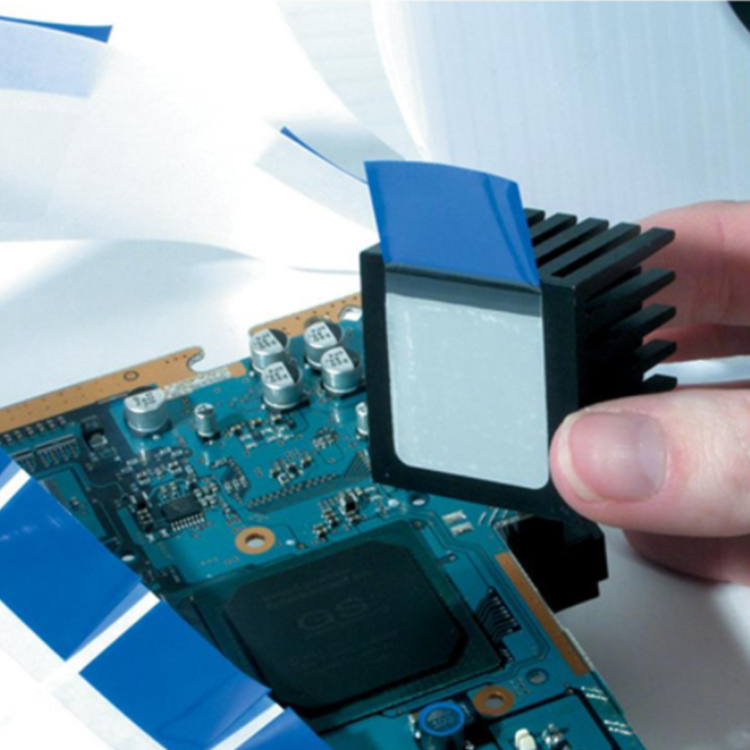

5. The standardization of thermal conductivity and heat dissipation, the use of thermal interface materials, and the purpose of heat dissipation in lamp shells are to reduce the operating temperature of high-definition display screen chips. Due to the significant difference in expansion coefficient between chips and commonly used metal thermal conductivity and heat dissipation materials, chips cannot be directly soldered together to prevent high and low temperature thermal stress from damaging the display screen chips.

The series of thermal conduction interface materials from Advanced Institute (Shenzhen) Technology Co., Ltd. are used to fill the air gap between heating devices and heat sinks or metal bases. Their flexible and elastic characteristics make them suitable for covering very uneven surfaces. Its excellent performance enables heat to be conducted from the heating element or the entire PCB to the metal casing or diffusion board, thereby improving the efficiency and service life of the heating electronic components.

Characteristics Table of Thermal Conductive Silicone Products

The Advanced Institute Company's series of thermal conductive interface materials fill the air gap between heating devices and heat sinks or metal bases. Their flexible and elastic characteristics enable them to be used to cover very uneven surfaces. Its excellent performance enables heat to be conducted from the heating element or the entire PCB to the metal casing or diffusion board, thereby improving the efficiency and service life of the heating electronic components.

Characteristics Table of Thermal Conductive Silicone Products

6. Heat dissipation through heat pipes, utilizing heat pipe technology to transfer heat from the display chip to the shell's heat dissipation fins.

7. Thermal conductive plastic shell, using thermal conductive plastic material during injection molding of the plastic shell to increase its thermal conductivity and heat dissipation capacity.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.avanzado.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2